Congress I+D PARCISA .14

PRESENTATION NEW SUPERLIGHT FOODSTUFF TANKER

| read 70861 times

Parcisa has presented during its 2014 R+D meeting, its new foodstuff model with ATP standards.

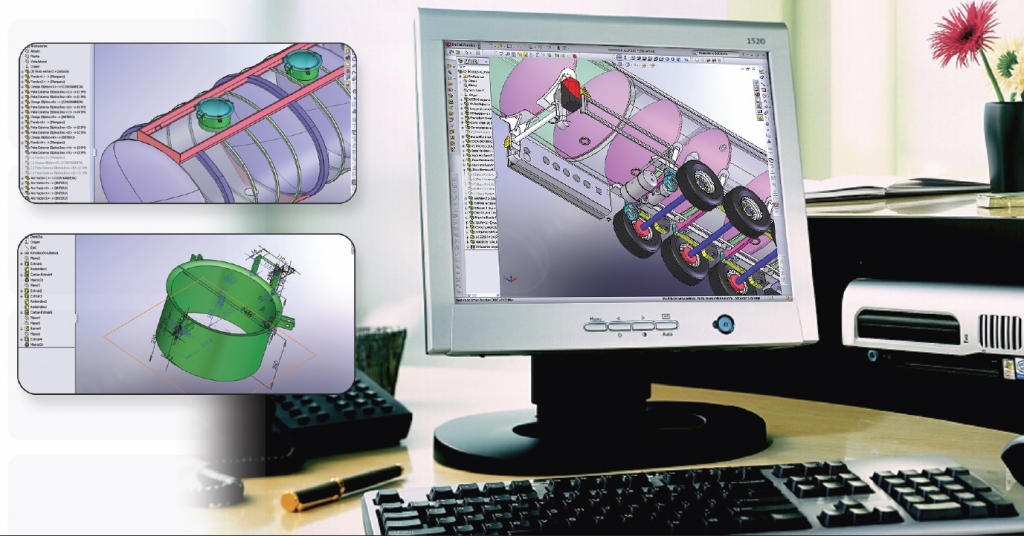

This new model has been developed in collaboration with Vehivial and the University of Zaragoza. All new virtual techniques and 3D models has been used to get a real model that has been exhaustive tested.

So, the tare weight has been reduced in 800 Kg comparing with the 30000 litres standard models made up to now. So, payload has risen by a 3% for a total capacity of 31000 litres.

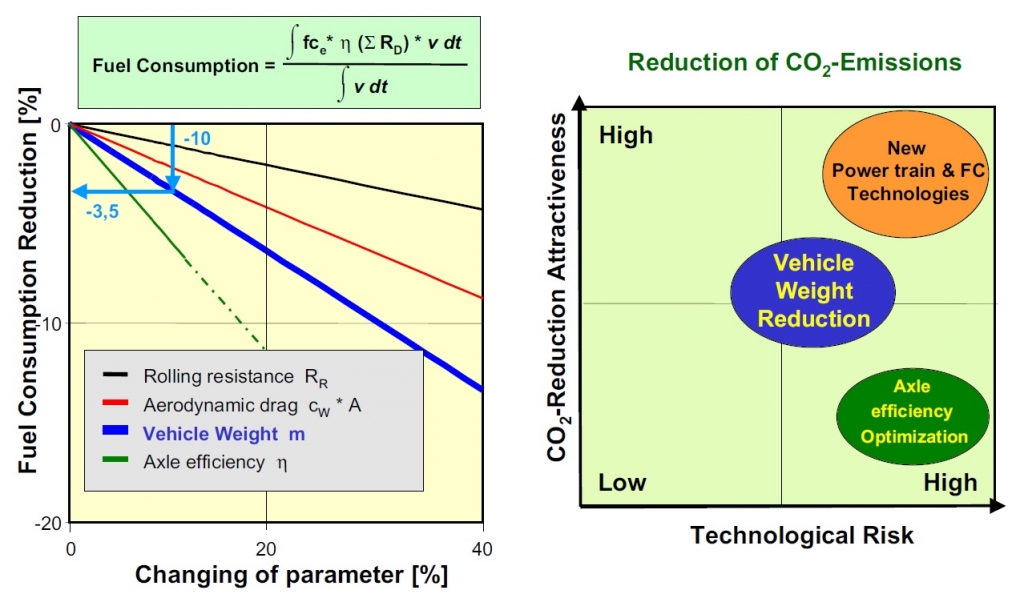

With a superlight tare weight of 5680 Kg, a fuel saving of 1 - 2,5 % has been estimated and so CO2 emissions reduced when the tanker roads empty. This also contributes to a less wear in wheels, brakes, axles, etc., that helps the customers to improve its competitiveness.

The tanker has already been tested by different customers for 2 years in order to get their feedback.

The meeting took place in Bodegas El Castillo (another company of the group) where more than 80 foodstuff operators were present in the presentation and visited the factory to see how Parcisa manufactures its tankers and all the quality tests that they support prior to be delivered.

A LIGHTER AND MORE SOLID SOLUTION

Optimized design of a high performance foodstuff semitrailer tanker, reducing the tare weight and thus increasing the payload capacity of the semitrailer.

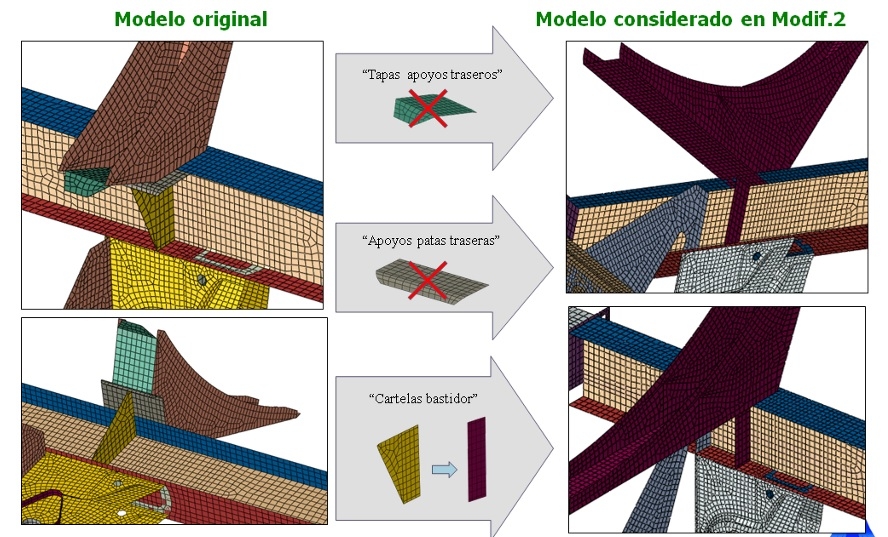

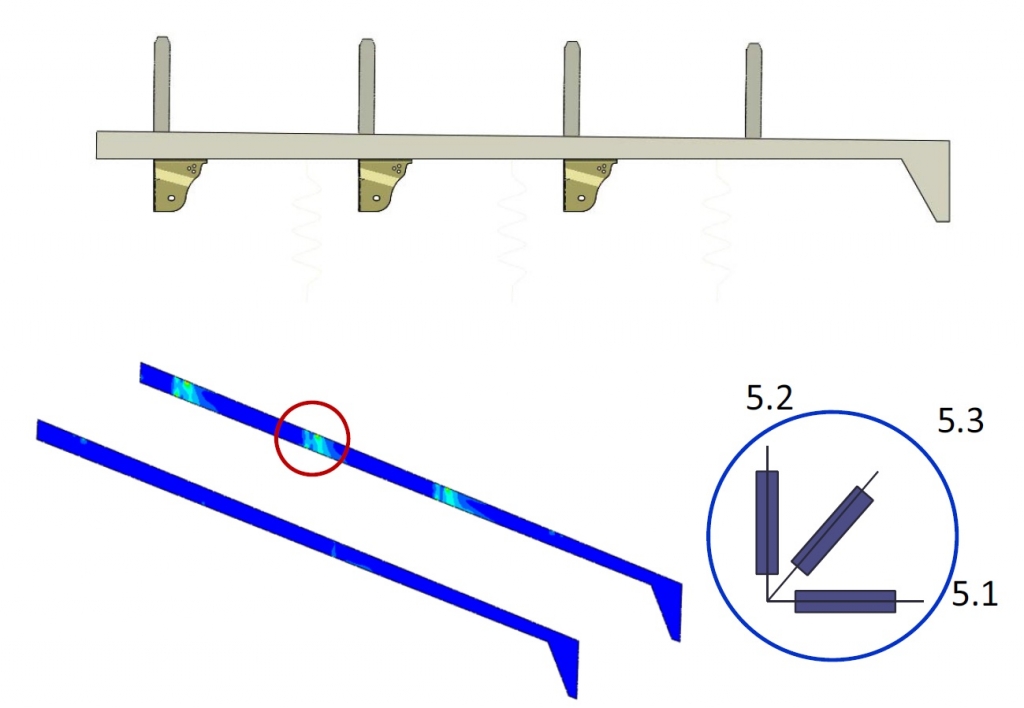

Developing of new optimizing designs for performance and reliability together with size and weight savings structural designs and high resistance materials, i.e., the NEW CHASSIS FRAME.

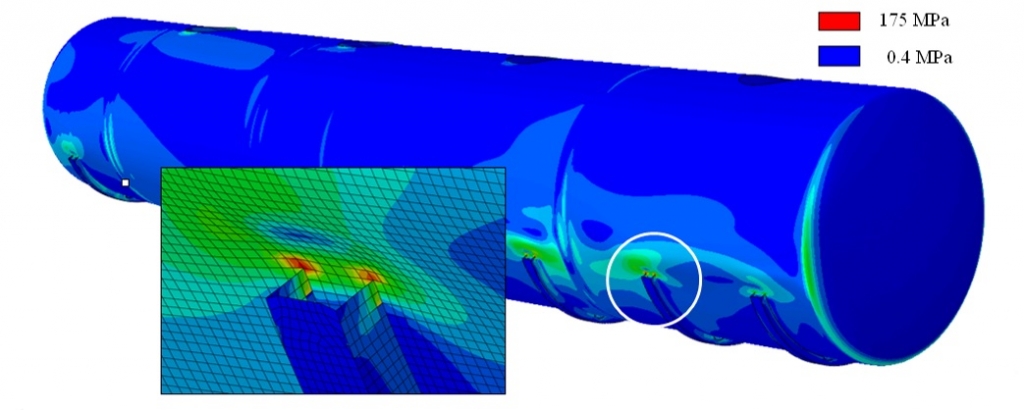

The project has been developed in collaboration with R + D centres, in an iterative process with CAD + FEA analysis, repeated until an optimal design is found to bring the new design to its optimum efficiency point.

PRODUCT CONFIDENCE

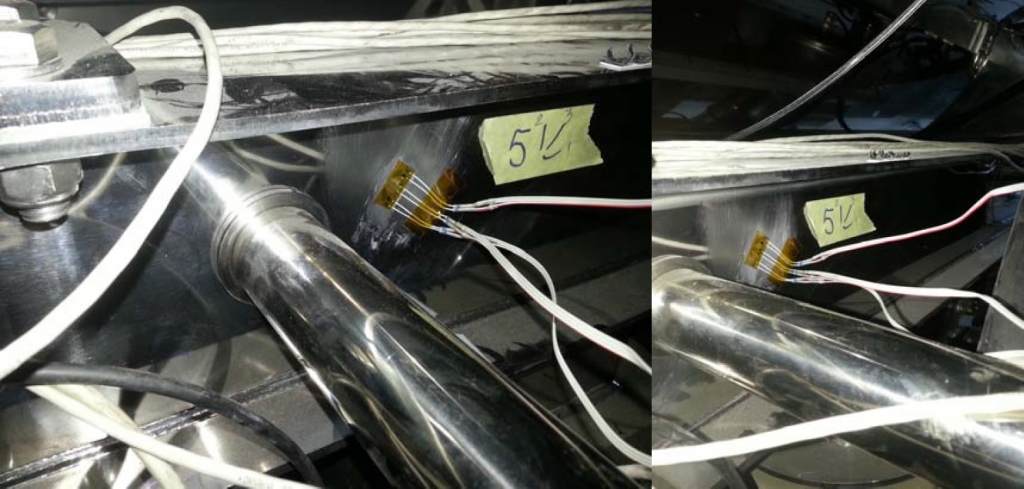

The exhaustive methodology followed by the University Technicians and our Engineering Team, has been carefully validated through experiment with real prototypes in ground tests.

2 years working with some of our customers as well as the continuous evaluation through periodic inspections guarantees this new design.

MORE PAYLOAD WITH LESS TARE WEIGHT

Weight saving: more than 10% of weight saving (800 Kg), comparing with similar units manufactured before.

More payload on each trip: 3% more in payload (1000 litres in this model), getting a more competitive semitrailer for transport companies in a fiercely competitive world.

Less consumption: estimated fuel saving of between 1% full charged and 2,5% empty.

Greener product: estimated CO2 emissions reduced between 4 to 5%.

PARCISA: INNOVATION AND RESEARCH

This product development pushes to Parcisa as a leader in the foodstuff tankers sector, with the lightest foodstuff vehicles in the European market.

Parcisa bets for the R + D as a key policy, and there is no doubt that the results of our innovative engineering efforts will be visible for the benefit our customers within the next few years.

This project has been funded by the European Regional Development Fund, ERDF within the Operational Programme 2007 -2013 Technology Fund